Rotary Level Switch for Bulk Materials

The SITRANS LPS200 is a rotary level switch designed for level and material detection in bulk solids such as grain, feed, cement, plastic granules, and wood chips. It handles bulk densities down to 100 g/l with the standard paddle and down to 15.06 g/l with the optional rectangular paddle, and it can detect full, empty, and demand conditions.

A slowly rotating geared motor with a slip clutch drives a rotating paddle that detects the presence of material. When material comes into contact with the rotating paddle, the rotation stops, which changes the switch state. Once the paddle is no longer covered by material, the rotation resumes, and the relay returns to its normal state.

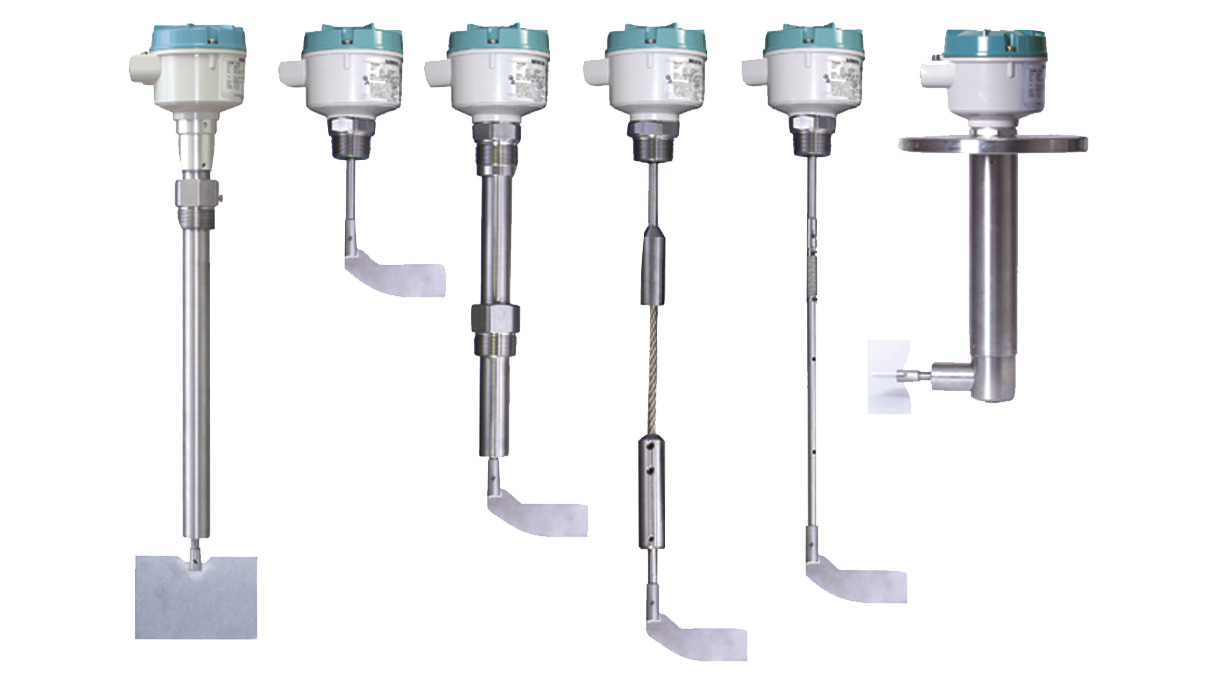

The LPS200 features a robust design and can be used with bulk materials even under harsh conditions. The sensitivity of the paddle can be adjusted according to material characteristics, such as buildup on the blade. The LPS200 is available in various configurations, including compact, extended, and cable-extended versions. It comes with a standard paddle that is effective in most applications, but can be configured with a hinged or rectangular paddle for increased sensitivity to lightweight materials.

The level switch is suitable for bulk solids such as grain, feed, cement, plastic granules, and wood chips.

Advantages

- Proven technology for bulk materials

- High-integrity mechanical seal

- Unique clutch mechanism prevents damage from falling material

- Rotatable housing for easy wiring

- Optional paddles for use with low-density materials

- Small paddle allows easy installation through existing process connections

- Available in a high-temperature version and with an optional extension kit

- Optional "fail-safe" configuration detects loss of rotation

- Functional Safety (SIL 2). The device is suitable for use in accordance with IEC 61508 and IEC 61511